Massima flessibilità per ogni richiesta di verniciatura

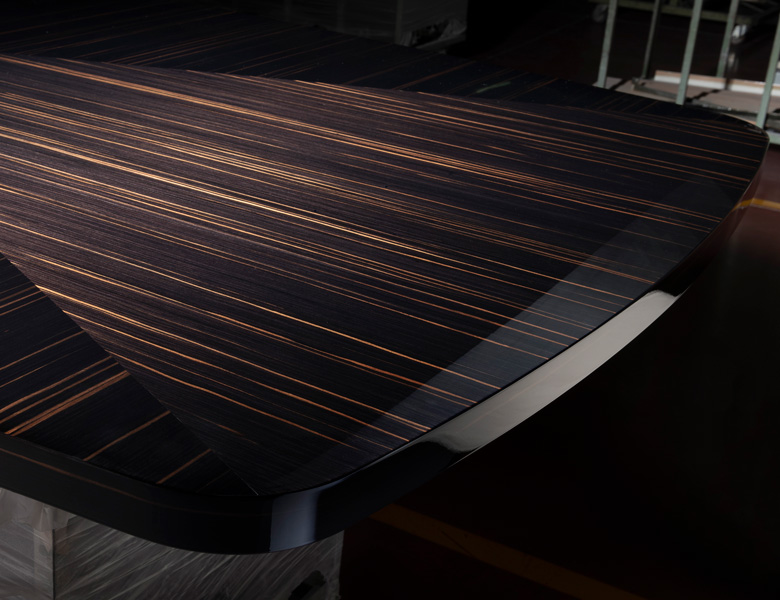

Con l’applicazione della finitura, tocca a noi dunque l’ultima delicata fase di lavorazione prima di arrivare al prodotto finito, fondamentale per esaltarne la bellezza, valorizzarne il design, definirne la qualità.

Garantiamo cura artigianale, servizio rapido e flessibile per ogni esigenza di verniciatura. Realizziamo colorazioni e finiture di pregio su qualsiasi essenza di legno, particolari in metallo ed espanso. Verniciamo con tecnica a spruzzo utilizzando vernici attentamente selezionate per ottenere le migliori performance visive, tattili e di durevolezza.

Supporti e tipologie di verniciatura

Tipi di lavorazioni

Supporti lavorabili

- Tutte le essenze del legno

- Laminati

- Particolari in espanso

- Particolari in metallo

- MDF

Finiture

- Laccati lucidi e specchiati

- Laccati opachi e satinati

- Metalizzati e perlati

- Goffrati e texturizzati

- Lucidi trasparenti

- A poro aperto

- Effetti Natural Wood

Tipologie produttive

- Media serialità

- Piccola serialità

- Produzioni ad hoc per falegnameria su misura

Il processo produttivo: tecnologia e sapienza artigianale

In Agostini Srl, dotazioni tecnologiche e manualità interagiscono. Se da un lato sono stati fatti passi da gigante nei macchinari, nella composizione e nella varietà delle vernici e nell’efficienza degli ambienti di lavoro, la nostra azienda ha sempre messo al centro l’uomo e la sua sapienza artigianale. E’ grazie al contributo di maestranze qualificate infatti che garantiamo al cliente verniciature e finiture di altissimo pregio.

Tre reparti di lavorazione come garanzia di qualità.

Ogni lavorazione Agostini fa capo a tre reparti, fisicamente separati fra loro: carteggiatura, verniciatura, controllo qualità e imballo.Questa separazione, oltre a garantire agli ambienti di lavoro la massima salubrità, evita la volatilità di polveri in verniciatura che potrebbero compromettere la perfetta resa della finitura.

Verniciatura

Grazie ad un mix composto da nuove tecnologie, dall’impiego delle migliori vernici, dalla manualità dei nostri operatori, siamo in grado di ottenere una verniciatura ad hoc per ogni lavorazione. Dove richiesto forniamo la nostra consulenza su resa e tipo di vernice ed una campionatura al fine di valutare la migliore soluzione.

Controllo qualità e imballo

Dopo l’asciugatura il prodotto viene esaminato otticamente e al tatto ed eventualmente lucidato. Il controllo qualità è l’ultima fase. Solo dopo averne nuovamente verificato la perfetta integrità, i prodotti vengono imballati singolarmente, per garantire massima protezione durante la spedizione.